BPF Pipes Group updates polyethylene pressure pipe systems guidance

The BPF Pipes Group has updated its guidance for engineers designing polyethylene pressure pipe systems for below-ground gas applications. Julia Trew, Standards and Technical Manager at BPF Pipes Group, outlines what’s new

Joining of polyethylene pressure pipes for below-ground gas applications is one of a series of best practice guides from the BPF Pipes Group. It details the three main methods for joining polyethylene (PE) gas pipes for pressure applications: electrofusion, butt fusion and mechanical fittings. It recommends the most appropriate solutions for different pipe sizes, pressure ratings and installation methods.

Gas distribution network operators require construction work to be undertaken in accordance with industry specifications to provide consistent, high-quality workmanship. The Gas Industry Specifications GIS/PL2 standard covers PE pipes and fittings for gas. All three methods of joining PE gas pipes are specified, which are now available free of charge from the Energy Networks Association website.

Members of the BPF Pipes Group manufacture PE pipes and offer all three methods of joining them for below-ground gas and other applications. The Group works closely with the gas and water industries to ensure specifications reflect current technology and best practice. The updated guidance for joining gas pipes is therefore complemented by similar guidance for water supply pipelines: Joining of polyethylene pressure pipes for below-ground water applications.

Each of the three methods of joining can provide long-term, leak-tight solutions. However, some are better suited to open-cut or trenchless installations. Tables in the updated guidance show and give reasons for the preferred method of joining, and acceptable alternatives are also listed. Guidance can also be sought from members of the BPF Pipes Group on specific situations.

Joining techniques

Butt fusion: PE pipes can be joined by using electrically heated plates under controlled conditions to fuse the ends together. Strong and reliable welds can be made by joining pipes or spigot fittings of the same diameter, thickness and polyethylene grade. When made correctly, butt-fused joints provide a leak-tight system that is fully resistant to end loads. GIS/PL2-3: 2021 is the current standard for butt fusion machines and related equipment.

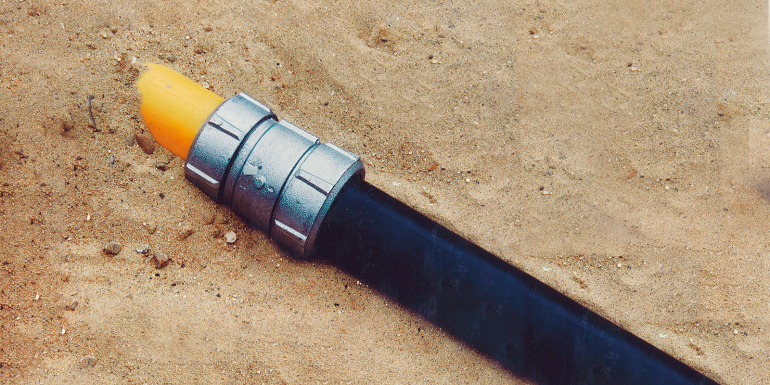

Electrofusion: Electrofusion fittings incorporate electrical heating elements that fuse a socket onto the end of the pipe. The GIS/PL2-4: 2019 standard covers fusion fittings with integral heating elements.

Electrofusion is a reliable method of joining two plastic pipes together in difficult conditions such as open excavation works. Well-made joints will have the same properties as the pipes that they join: long lifetimes, corrosion resistance and the flexibility to respond to ground movement. Part 6 of GIS/PL2 (namely, GIS/PL2-6: 2018) applies where PE pipes are connected to spigot end fittings by electrofusion or butt fusion. Where live connections to gas or water distribution mains are required, branch saddles can be installed directly onto existing PE pipes. This technique is illustrated and described by the BPF Pipes Group guide Branch connections for water and gas mains.

Mechanical fittings: These achieve a pressure seal by using elastomeric seals or gaskets that are tightened via bolts or compression rings. The three main types of mechanical fittings are:

- stub flanges – used to connect a PE pipe to a metal pipe or valve

- compression fittings – used to connect a PE pipe to another pipe (PE or metal); and

- screw fittings such as service head adaptors and garden fittings – used to connect a PE service pipe to a property network.

Mechanical fittings for use with PE pipes for gas supply are manufactured to the recently updated GIS/PL3: 2022 or BS EN 1555-3.

Download the guidance at bit.ly/ENAguides

Visit the Energy Networks Association website at energynetworks.org