The impact of coatings on combustion

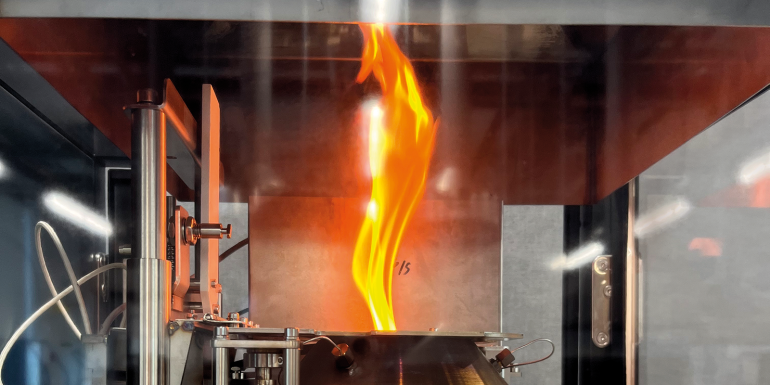

Cone calorimeter test in progress

Enya Zhang, a student at the University of Central Lancashire, has completed IFSM-funded research exploring the impact of coatings on wood combustion.

Wood is increasingly promoted as a sustainable option for building exteriors and façades due to its many environmental advantages. Wood is renewable, breaks down naturally, has a low environmental impact and offers excellent insulation and flexibility in design. As efforts to reduce carbon emissions in construction grow, wood has seen a renewed interest as a sustainable choice.

Nevertheless, wood has some limitations. It can be affected by exposure to sunlight, rain, fungi and insects, which can cause it to degrade over time. To improve its longevity, wood requires regular care, such as applying protective coatings or treatments. Another concern is that wood is naturally flammable, which poses safety challenges. These risks can be managed by using fire-resistant treatments, such as special coatings or preservatives, to improve its fire safety. It is worth noting however, that some of these treatments can influence how wood behaves when exposed to fire, making careful selection essential to ensure compliance with safety standards.

The ‘Experimental Study of Effect of Coatings on Combustion Characteristics of Wood’ project originated as Enya Zhang’s undergraduate research internship at the University of Central Lancashire in 2023 and was expanded with Institute of Fire Safety Managers’ (IFSM) support in 2024 to help the advancement of fire safety knowledge. The study examined how wood preservatives affect the burning behaviour of Swedish pine decking (due to its widespread use in construction and furniture).

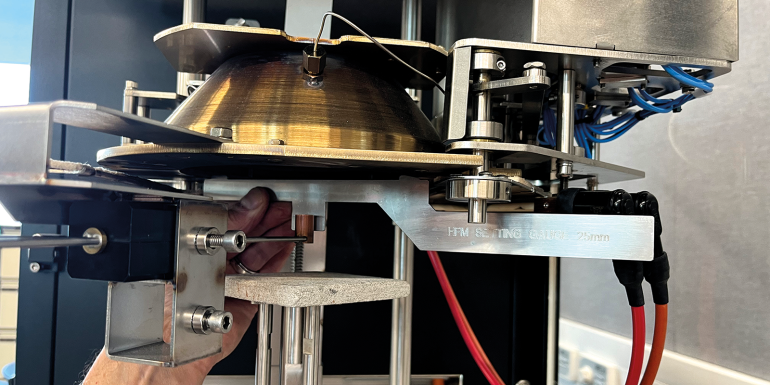

Calibration of cone calorimeter

Behaviour under heat

Pyrolysis refers to the thermal decomposition of materials when exposed to high temperatures in the absence of oxygen. Wood’s fire performance is largely influenced by its composition, which includes three main natural polymers: cellulose, hemicellulose and lignin. Each of these breaks down at different temperature ranges.

Cellulose, the primary structural component of plant cell walls, decomposes and releases gases at temperatures between 240 and 350°C. Hemicellulose, a less stable polymer found alongside cellulose, decomposes at lower temperatures – around 200 to 260°C. Lignin, a complex polymer that gives wood its rigidity, has a broader decomposition range of 280 to 500°C. These differences in decomposition temperatures influence how wood behaves under heat.

When wood is exposed to heat, water is the first to evaporate at around 100°C. Once the wood dries out, it begins to degrade, releasing volatile gases such as formaldehyde, carbon monoxide, carbon dioxide, hydrocarbons and other compounds. Alongside these gases, a solid residue known as char is formed. Char acts as a protective layer, insulating the remaining wood beneath it from further heat penetration and slowing down the pyrolysis process. Fire-retardant preservatives help increase the amount of char formed when wood is heated.

Wood powder sample filled in aluminum crucible to be tested in thermogravimetric analysis

The experiments

Using a cone calorimeter (which measures key parameters such as heat release rate, ignition time, smoke production and mass loss during combustion), the heat release rates and ignition times were measured for five different samples treated with three types of water-based preservatives. The cone calorimeter is particularly valuable to evaluate their effectiveness in slowing down or mitigating fire spread. These results were then compared to untreated samples and those treated with fire retardants.

Heat release rate (HRR) and peak HRR are critical metrics used to assess the flame retardancy and flammability of construction materials, including wood. HRR represents the rate at which a material releases heat during combustion, while the peak HRR indicates the highest rate of heat release observed during a test. Both parameters help evaluate how materials perform under fire exposure, such as how easily they ignite and how intensely they burn.

For further insights, thermogravimetric analysis was carried out to study how the samples reacted to heat. This helped identify reaction rates and key temperature points, which can be used to develop models for fire safety engineers, product designers and fire simulation tools.

The experiments showed that higher heat exposure caused all samples to ignite faster. Additionally, samples treated with wood preservatives and fire retardants produced more carbon monoxide when exposed to higher heating rates. The findings suggest that applying preservatives after a fire-retardant coating can reduce fire performance. The degree of impact depends on the composition and concentration of the preservatives.

While this research was an academic study, the results do have practical implications. As Zhang states: “Boron-based fire retardant can effectively reduce the peak and total heat release rate and postpone the time of ignition. However, it increases the CO production rate, which may pose risks to occupants during evacuation.”

The results of this research have already been shared at the Fire Safety Façade and ICFSER conferences. The IFSM hopes Zhang’s study findings will be of interest to fire engineers and safety professionals, providing valuable insights into the interaction between fire retardants and wood treatments.

The full research findings are available at b.link/IFSM_research

Legislation

In the UK and internationally, there are various guidelines and standards for preserving wood. One of these is BS EN 350, which outlines how wood should be tested and classified based on its durability and how well it responds to treatments. Wood is rated in categories from ‘easy’ to ‘extremely difficult’ for treatment and ‘very durable’ to ‘not durable’ for longevity.

Another standard, BS 335, is similar to BS EN 350 in its classification approach, but focuses on how wood and wood-based products withstand environmental exposure – with ratings from Class 1 to Class 3 based on their susceptibility to damage.

The UK Building Regulations, particularly Part B, establish legal requirements for fire safety in buildings. These include provisions for warning systems and escape routes, controlling fire spread within structures and ensuring fire safety for building exteriors. Approved Document B provides detailed guidance on meeting these requirements, referencing standards such as BS 9999 and BS 7974-6 for complex building designs that need tailored solutions. These documents regulate the fire resistance levels of materials used in different parts of a building, specifying classification grades based on standardised tests. However, none of these standards address or warn about how coatings applied to wood façades might affect their fire safety once the materials are in use.