Why net-zero design needs to improve

Scott Wilson, head of sustainability at Black and White Engineering, discusses net-zero design and looks at how the sector needs to improve.

The pressure on the engineering and construction sector to design, create and build greener, cleaner buildings has never been greater. Historically, buildings have claimed to be net-zero carbon, but the methodologies used to assess this have been flawed: they do not include all end uses and the inputs are too generic to adequately predict energy consumption.

For example, the construction industry uses thermal modelling in line with Part L of the Building Regulations to assess the energy efficiency of a building. That is, a building is considered to be net-zero carbon when the net emissions from the energy consumed by fixed building services are less than or equal to zero. By using the Building Regulations methodology, if all of the regulated energy (i.e., the energy assessed via thermal modelling) is offset by a low-carbon source, the building was claimed to be net-zero carbon.

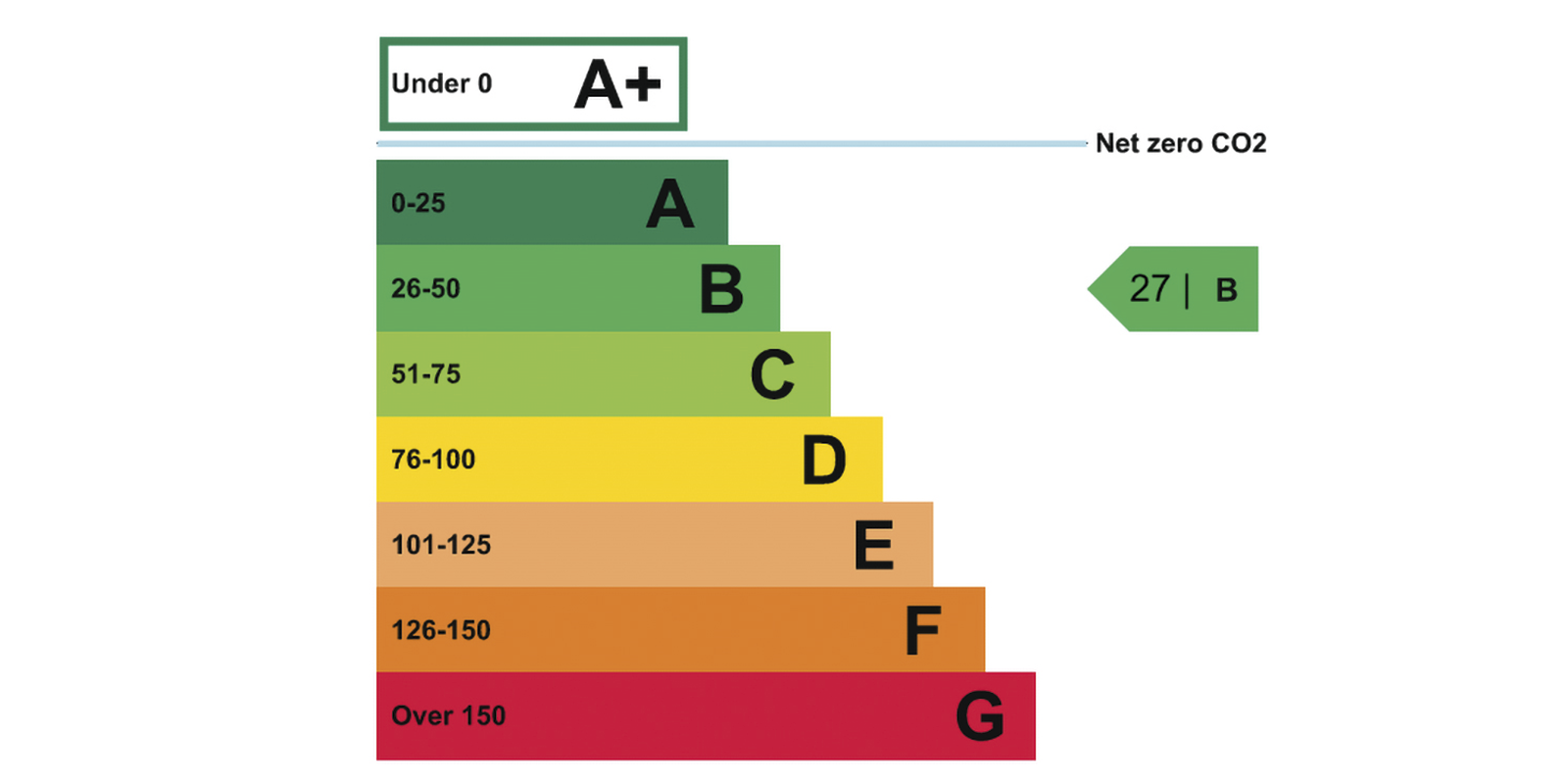

While the regulations do not feature a requirement to make buildings net-zero carbon, this modelling methodology could be used to make that claim – even though the methodology excludes a lot of end uses. This is particularly prevalent in Energy Performance Certificates (EPCs), which are a requirement of Part L. For example, if the B-rated building pictured below had enough renewable energy on-site to offset the regulated energy, it would have a rating of A+ and would be considered net zero under the Building Regulations, even if emissions falling outside the regulations were not offset.

The industry is moving past this approach and is considering more detailed modelling methodologies coupled with assessment of actual operational energy data after a building is occupied. This will enable the sector to more justifiably make claims that buildings are net-zero carbon.

Until then, a building’s net-zero credentials are assessed either by meeting all on-site demands through low carbon energy, or by generating enough renewable energy on-site or nearby to offset the emissions from fixed building services.

This scope is limited, as commercial buildings such as offices have significant small-scale power loads that can account for more than 50% of a structure’s energy demand. Furthermore, on-site renewable energy generation may not coincide with the building’s energy demand, resulting in times when the building still requires a conventional means of obtaining energy such as through the National Grid or using fossil fuels. Part L is a design issue only, and no follow-up is required to ensure that the building is performing as predicted.

Although this methodology serves to reduce carbon emissions, the scope of end uses covered is too narrow and is not an accurate prediction of a building’s energy consumption when in use. The UK Green Building Council (UKGBC) methodology looks to remedy this by including all of a building’s end uses.

The UKGBC’s framework addresses the gap between predicted and actual energy consumption by using real-life data from meter readings, utility bills and so on. In doing so, this encourages architects to work towards a much more accurate simulation at the design stage so that options for reducing a building’s energy demand can be tested and energy consumption can be minimised as much as possible. As this is based on actual consumption data, claims of a net-zero carbon building carry credibility; the industry is already seeing a significant uptake in designs targeting net-zero carbon under the UKGBC’s framework.

Embodied carbon

The amount of carbon embodied within the materials used in a building’s structure and emitted during the construction process can often be larger than the building’s operational emissions, but this is often not considered unless specified by local planning authorities. There are no measures in the Building Regulations aimed at driving down embodied carbon.

By considering embodied carbon, significant reductions in a building’s overall emissions footprint can be made by choosing different materials, such as using a timber frame instead of a steel frame. By undertaking a detailed lifecycle assessment early in the design stage, efforts can be focused on the elements with the highest embodied carbon, such as the superstructure.

Detailed energy modelling is required to predict a building’s energy demand. All plant performance parameters must be considered, such as part load efficiencies to show how a building will operate under different conditions. Stress test modelling must be included to take into account the unpredictable nature of building occupants – the way they use a building can have a significant effect on its energy consumption. Once an energy model is built and a performance baseline has been determined, this can be used to decide the best strategy for the building.

Embodied carbon is calculated using a whole lifecycle carbon assessment. Every material used in the building must be quantified and its associated carbon emissions determined. Where available, an Environmental Product Declaration (EPD) for the product is used to determine its carbon emissions per tonne or by volume. If an EPD is not available, a base value determined via software can be used, but this is considered to be less accurate.

Net-zero upskilling

The methodology required to predict operational energy modelling is not typically used in the UK or in the industry as a whole, which means workforces will need to upskill to use the more detailed software plug-ins required to run these models.

When designing a building, teams will need to think holistically and understand that trade-offs must be made between reducing operational energy and reducing embodied carbon. For example, using triple glazing may reduce a building’s heating demand but will significantly increase the embodied carbon and therefore may not be the best option.

A major obstacle to completing accurate lifecycle assessments is the lack of manufacturers with EPDs. Many manufacturers do not currently have accredited EPDs, making it impossible to determine embodied carbon emissions. This means default database values must be used, but these can be very different from the performance of the actual products.

As the industry catches up, manufacturers with accredited EPDs are more likely to be used, giving them a competitive advantage. Following the 2021 United Nations Climate Change Conference last November, it is clear there must be a seismic shift in efforts to mitigate the effects of climate change. With energy consumption from buildings accounting for approximately 30% of the UK’s total emissions, the engineering and construction sectors need to make better use of the measurement tools available and cross-reference known data in order to produce better designs.

Learn more about net-zero construction at bw-engineering.com