CROSS UK: Critical issue with staircases in public building discovered

Collaborative reporting for safer structures. Report 1327: Critically under-designed moment splice connections.

Discovery of a critical issue with the staircases in a public building

During a site visit to a major development of a public building, the reporter found critically under-designed moment splice connections located at the midspan of the stringers of three nine-metre-span staircases.

While strong enough to allow the erection and light loading of the structures (two of the three stairs were built when the problem was identified), the connections may not have been adequate with full crowd loading on the stairs. These loads would occur in practice as the stairs would be heavily loaded as people leave the building.

The inadequate connection was spotted by the reporter, an experienced steelwork and steel joint designer, who was employed to advise on the temporary works needed to facilitate the erection of a fourth stair (with a different geometry) located next to the third defective stair. It was good fortune that allowed this problem to be identified while the structure was under construction. If any of the joints had failed under loading, the stair, which was simply supported at both ends, would have collapsed with severe consequences.

Enquiries by the reporter, with the co-operation of the steel fabricator responsible for the connection design, revealed that an inexperienced designer had used proprietary software to design the joint.

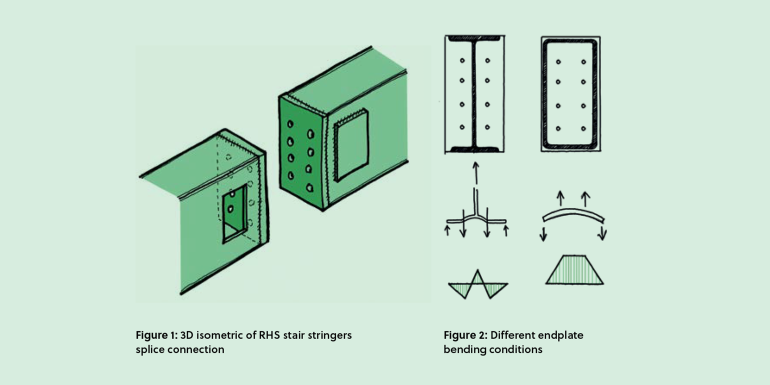

The stair stringers were large (400 x 200mm) Rectangular Hollow Sections (RHS) (as shown in Figure 1, on the next page), and the software did not support this section type. The designer then substituted a 406 x 178mm Universal Beam section in the calculations and ran the software on that, concluding that 10mm endplates were adequate. Based on experience, the reporter would anticipate that an endplate between two and three times thicker would in fact be required.

The reporter notes that the proprietary software uses a T-stub model to assess the endplate – a situation that assumes double curvature bending and a central web welded to the endplate. The reality is that the endplate is in (two-way) single curvature bending and is restrained only around its outer edges, as shown in Figure 2. Thus, the bending of the plate is totally different from that assumed in the calculation model and the verification calculations are basically meaningless.

This issue was not caught by the main design team’s structural engineer, who checked the proposals. It was also not picked up by the certifying engineer.

In the reporter’s view, the issues of inadequate first principles understanding by underqualified design staff, overreliance on software and failures in checking are apparent in their example. Furthermore, they believe a general lack of understanding of the issues in the steel fabrication industry means that errors of this nature are less likely to be spotted.

In this instance the matter was resolved by on-site full penetration butt welding of the RHS stringers, making the defective joint redundant.

Comments

It is very disappointing, and worrying, that the defective design got through all levels of formal checking without being spotted. What is positive is that it looks like – once the issue was identified by the reporter on-site – it was dealt with robustly and for that they must be commended.

The Hyatt Regency walkway collapse in Kansas City in 1981 is a stark reminder of what can go tragically wrong when connection designs are overlooked. This resulted in the deaths of 114 people and serious injuries to 200. In 2000 Ken Carper, a prominent US forensic engineer, asked the question: “Have the design and construction communities really adopted changes that will prevent the recurrence of a similar tragedy?”

This report further highlights the benefits of having an experienced eye on-site to identify any potential issues that may arise. Had the staircases been subjected to the full crowd loading, it could have proved disastrous. All those with influence or control in the design process should recognise the potential severity and undertake a full review of their processes and procedures.

Further reading

Below is a suggested resource list for anyone starting off in steel connection design:

- The Green Books on SteelConstruction.info

- Structural Steelwork Connections by Cheal and Owens

- Advisory Desk Notes on SteelConstruction.info

- Guide to Design Criteria for Bolted and Riveted Joints by Kulak, Fisher and Struik

In steelwork, connections are normally the weak link. In the industry, we have a fundamental industry skill problem in the division of labour between main designers and connection designers. While commercially efficient, the division inhibits main designers building up their own connection design skills. Designers need to learn what looks right without any calculations at all. This starts with learning to proportion a connection according to the size and configuration of the members it is attached to. It also implies the obvious strategy of not wasting that member’s potential capacity by putting on a grossly undersized connection whatever the theoretical forces.

While this report focuses on the theoretical, it is a practical subject and those who build things should have an intuitive feel for what is going to work. How do you instil practicality into people who have spent the majority of their careers staring at a screen with very little time on-site? This might be a topic that would benefit from a survey of the industry.

Another reoccurring issue is the overreliance on design software and trying to manipulate models to design a connection or a component that is outside the program’s design capabilities – for example, splice connection design for I-sections inappropriately used for hollow section members. Careful consideration is required to identify what design implications there might be when this is done.

To subscribe to the CROSS UK newsletter (structural and fire safety concerns), visit cross-safety.org/uk/user/register

Key learning outcomes

For steel connection designers:

- connections can often be the weak link in structures, and can be a key interface between two design teams, so always need verification

- designers and checkers need to match connection design proportionally to the size of member provided. Main designers should always verify that key connections (as designed) accord with design intent; and

- computer analysis requires care in modelling, verification of models and software, and validation of results. Beware of overreliance on computer results.