When district heat networks meet existing buildings

In the race against time to decarbonise, plans are afoot for district heat networks to bring a solution, but how does this fit with the existing building stock, asks Andrew Pearson

District heating networks (DHNs) transfer heat, and sometimes cooling, from a central source to buildings through a series of large-diameter insulated pipes.

A major benefit of this approach is that it makes it easier and more cost effective to use low-carbon heat sources, such as recovered waste heat from industry or geothermal heat from rivers and the ground.

The Department for Business, Energy and Industrial Strategy (BEIS) envisages central government working with industry and local stakeholders to identify and designate areas in England where DHNs will be the cheapest solution for decarbonising heating. The government consultation on proposals for heat network zoning in England closed in November 2021; the BEIS is analysing the feedback. If its initial proposals are adopted, certain buildings within declared zones will be mandated to connect to a DHN.

According to the consultation, investment in heat networks is being hampered by high upfront capital costs, long payback periods and the risk and uncertainty of building occupiers reneging on the commitment to connect to a network. The zoning proposal is intended to tackle these barriers by providing investors with assurance on connections because of the mandatory requirement for key buildings to connect to a DHN, as long as it is “cost effective (and practical) to do so”. Under the current proposals, all new large public sector and non-domestic buildings and communally heated domestic premises “would be required to connect to a heat network within a prescribed timeframe”.

An insight into how the zoning proposal could influence building design can be found in London. Under the London Plan, if an existing DHN is unavailable, major residential developments are required to incorporate a communal heat network rather than use individual gas boilers. This approach is intended to make it easier to decarbonise heating in the future because only a single heat source will need to be replaced for a development rather than individual boilers in dwellings.

Currently, DHNs provide approximately 2% of the UK’s heat demand. The Impact Assessment accompanying the consultation estimates the zoning proposals could increase this contribution to about 7% of UK heat demand, with an additional 31TWh of heat deployed up to 2050.

The DHN zoning proposal is underpinned by the Chartered Institution of Building Services Engineers (CIBSE) document CP1: Heat Networks: Code of Practice for the UK (2020). CP1 is a voluntary code of practice that sets out the minimum standards for a DHN system. It is likely the government’s zoning proposal will use CP1 to determine the minimum standard a DHN must achieve.

To accompany CP1, CIBSE has also published Design Guide: Heat Networks. This is a technical document for building services design engineers with a focus on system design, pipe sizing and thermal storage to help them maximise carbon savings from a central heat source.

Citigen network

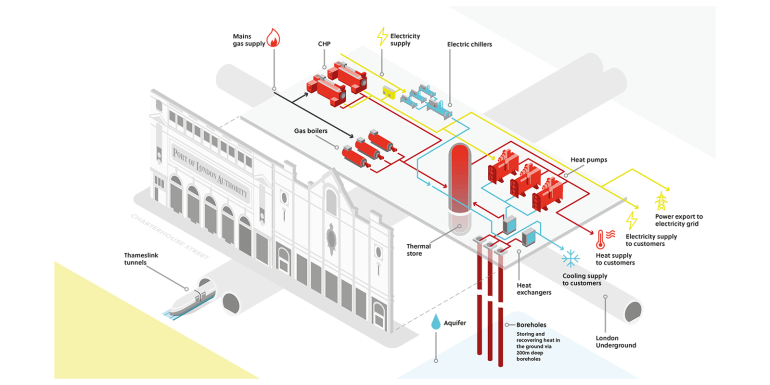

The design of DHNs is often technically challenging because they frequently supply heat to existing commercial and residential buildings as well as new buildings, which often have very different and more specific system requirements. This is the case in the City of London, where E.ON’s Citigen network supplies up to 40GWh of heat and 7GWh of cooling to the City of London’s Guildhall, Barbican Centre and the Museum of London over an 11km network of insulated pipes.

Citigen’s central plant, located next to Smithfield Market, uses two 4.3MW gas-fired combined heat and power (CHP) generators that produce electricity to power the network’s pumps as well as chillers to provide the centralised cooling, with surplus electricity sold to the grid. Waste heat from the engines and chillers is collected for use in the heat network. The plant also includes three heat pumps and three 450mm diameter boreholes to enable the scheme to utilise an aquifer 200m below the City as a geothermal heat source and heat store.

While the system serves new buildings with underfloor heating, which only require heat at 45°C, it has been designed with a much higher flow temperature of 85°C because it serves many older buildings with legacy systems, such as the Guildhall. To supply the newer buildings, the network temperatures are lowered at the heat exchanger interface between the heat network and the building.

Over time, as the older buildings are refurbished and made more energy efficient, E.ON is expecting to lower the system’s temperature to help further improve its efficiency.

E.ON is also looking at adding a lower-temperature network to Citigen to serve a new area south of the current network. It has already undertaken a pre-feasibility study on how to expand the system with a view to installing a fifth-generation DHN (see box).

GreenSCIES

In the north London borough of Islington, the design of a fifth-generation DHN is already well under way as part of the GreenSCIES initiative. The first phase of the scheme will connect three council-owned residential blocks and, crucially, an existing data centre. Fundamental to the fifth-generation scheme is a two-pipe ambient loop; the warmer of the two pipes is designed to carry about 15°C and the cooler one approximately 10°C. This will allow low-grade thermal energy to be exchanged between buildings that require both heating and cooling.

Heat recovered from the data centre’s water cooling system will provide the network’s primary source of heat, and will be distributed by the warmer of the two pipes. Customers requiring heat will connect to the ambient loop through a local heat pump system.

For older buildings, the heat pump will take the low-grade heat from the warmer of the two pipes and raise its temperature to 75°C – hot enough to enable the DHN to meet the needs of the existing heating and hot water systems in these buildings. Once the heat has been extracted, the water is returned to the data centre through the cooler of the two ambient loop pipes, where it will be used to provide cooling.

To maximise both the economic and carbon benefits of using an ambient loop, heating demand needs to balance with the cooling load across the network. When it is not possible to balance short-term heating and cooling loads, the system will use an aquifer thermal energy storage system to supplement the shortfall. This will also provide a means to store surplus heat between seasons.

When complete, the first phase of the scheme is expected to save more than 5,000t of carbon dioxide annually. The aim is to roll out GreenSCIES over a significant area of Islington to supply low-carbon heat to more than 10,000 residents in 3,500 homes, along with up to 70 businesses.

Swaffham Prior

While the above examples are in London, not all DHNs are in cities. One of the biggest and most urgent challenges in decarbonising heating is in rural communities, many of which are not on the gas network.

Swaffham Prior in Cambridge is England’s first rural DHN. The majority of the village’s 300 homes – as well as two churches, a pub and a school – are currently heated with oil, one of the most carbon-intensive forms of heating. In the coming months, the first of its homes will be connected to a new DHN, which is supplied with low-carbon heat from a hybrid air- and ground-source heat pump system powered by a nearby solar farm.

The project is a partnership between Swaffham Prior Community Land Trust and Cambridgeshire County Council (CCC). To get it up and running, CCC had to engage with the community to ensure sufficient numbers of homes wanted to buy the low-carbon heat.

More challenging was establishing the likely heat demand from the village when the main guide to heat consumption was the delivery notes for heating oil. To help the designers build a more detailed picture, heat meters were installed in five archetypal properties. The final estimated heat demand was based on a combination of heat meter data and various other sources to calculate approximate total heat usage.

A Heat Supply Agreement also had to be drawn up. The DHN is effectively a utility; to ensure residents don’t pay a premium for their community-supplied heat, the tariff has been linked to the price of heating oil. Consumer protection is expected to be provided by Ofgem, the regulator for DHNs.

A major technical challenge was ensuring the DHN’s compatibility with a diverse range of dwellings, some of which were listed. As a consequence, it had to be designed to supply heat at around 72°C, roughly the same temperature as the oil-fired systems it is replacing. The network’s relatively high temperature will enable residents to dispense with conventional oil-fired boilers and connect directly to the network through a simple heat interface unit (HIU) without having to upgrade radiators or add insulation in their homes. Internal disruption will be minimal because the HIUs will generally fit in the space previously occupied by the boiler; however, some external disruption will occur because trenched pipework must be installed to connect the property to the DHN.

The target is to connect 100 properties in the first 12 months, with 75% of all dwellings connected in five years. When it is fully operational, the retrofitted DHN is projected to save more than 47,000t of carbon annually.

While Swaffham Prior shows that by retrofitting a DHN it is possible to phase out fossil fuel heating even in a village, what all of these schemes show is the potential for heat networks to help to decarbonise heating and help the UK meet its carbon commitments. Moreover, the schemes show that DHNs are not the preserve of new builds and purpose-built systems, but the existing building stock too. It’s time to move with haste.

Heat networks through the generations

- First generation: These originated in the US in the late 1800s. They used coal-fuelled boilers in a centralised plantroom with high-temperature steam as the heat carrier.

- Second generation: First appearing in the 1930s, these used coal- or oil-fuelled centralised boilers with pressurised hot water as the network heat carrier at temperatures over 100°C.

- Third generation: Most of the UK’s current heat networks are third-generation systems, with heat provided by a centralised gas boiler or CHP in an energy centre. Heat is delivered to buildings on the network through insulated pipes and is typically supplied at 80-90°C.

- Fourth generation: These are similar to third-generation schemes in that heat is supplied from a centralised plant but at a lower temperature, usually below 70°C. This helps reduce distribution energy losses and improves operational efficiency in systems served by heat pumps or using waste heat.

- Fifth generation: These are radically different from previous generations because they operate at temperatures lower than 25°C, while heat production is decentralised and often uses waste heat. Individual heat pumps typically take low-grade heat from the network and raise its temperature to heat a building.

Government heat zoning proposal: bit.ly/DHNzoning

Design Guide: Heat Networks: bit.ly/CIBSE_DHNs

CP1: Heat Networks: Code of Practice for the UK: bit.ly/DHNcode